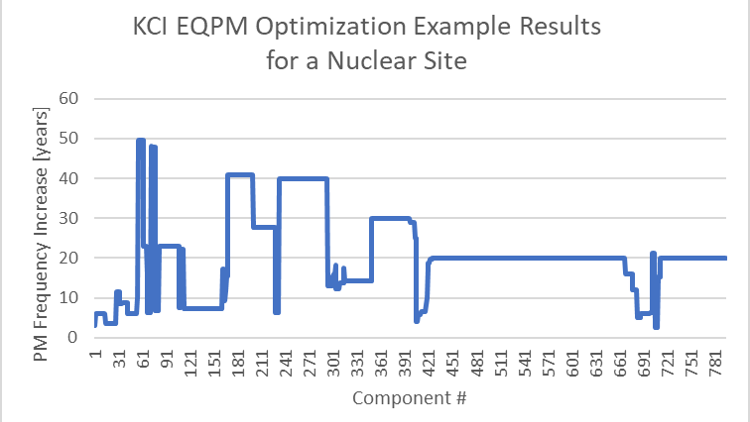

Over the past several years, KCI has been leveraging our vast amount of Equipment Qualification (EQ) experience to optimize Preventative Maintenance (PM) programs for numerous plants (EQPM). On average, KCI has been able to extend (or eliminate) 70% of the EQ PM programs analyzed. Along with EQ PM programs, KCI would enjoy the opportunity to optimize all the other PM programs at your site. The following is an example of KCI's EQPM experience:

- Constellation (previously Exelon) Fleet-wide EQ Preventive Maintenance (PM) Project:

- Challenged the current PM frequency

- Identified conservatisms and potential opportunity for improvements

- For an example site (Clinton Power Station):

- 262 PMs examined

- 70% extended for 7 component types.

- Exelon expanded the effort to examine its entire fleet under a corporate initiative

- Common component types across the fleet

- Transmitters

- Limit Switches

- Solenoid Operated Valves

- Other components noted for potential savings

- Relays, AC & DC MCC Buckets, Trip Units, Radiation Detectors, Motor Rewinds

- Resulted in projected savings in excess of $30M due to:

- Equipment replacement avoidance

- Design Modification for obsolesce avoided

- Costs for procurement, planning, installation, dose, scaffolding, disposal avoided

To learn more about our EQPM Optimization services, capabilities and experience, please Contact Us.

References:

(1) Constellation PM Project: 32nd Annual EQ Technical Meeting presentation, “EQPM Extension Project” by Exelon & KCI. LINK